Digital Manufacturing

Digital Manufacturing

Helping manufacturers adopt and implement Digital Technologies to support productivity and automation.

BrookConsult’s team of specialist Digital Manufacturing consultants work with your business to help you identify and embed digital technology into your processes to enhance efficiencies, procedures and quality.

We will work with you to develop your technical specificiation and provide detailed implementation planning, including risk analysis & mitigation, to ensure your investment in your technology selection and approach is the best solution.

Say goodbye to unexpected downtime. With AI-driven predictive maintenance, manufacturers can cut unplanned failures by as much as 70% and reduce maintenance costs by 25%.

What is Digital Manufacturing?

Digital manufacturing refers to the use of digital technologies, such as computer-aided design (CAD), computer-aided manufacturing (CAM), and advanced data analytics, to design, simulate, and produce products more efficiently and flexibly. It encompasses a range of processes and tools that integrate data from various stages of the manufacturing process – from design and prototyping to production and supply chain management.

Key elements of digital manufacturing include:

- Digital Twins: Virtual models of physical assets or systems that allow for real-time monitoring, simulation, and optimisation.

- 3D Printing/Additive Manufacturing: The process of creating physical objects from digital designs by layering materials.

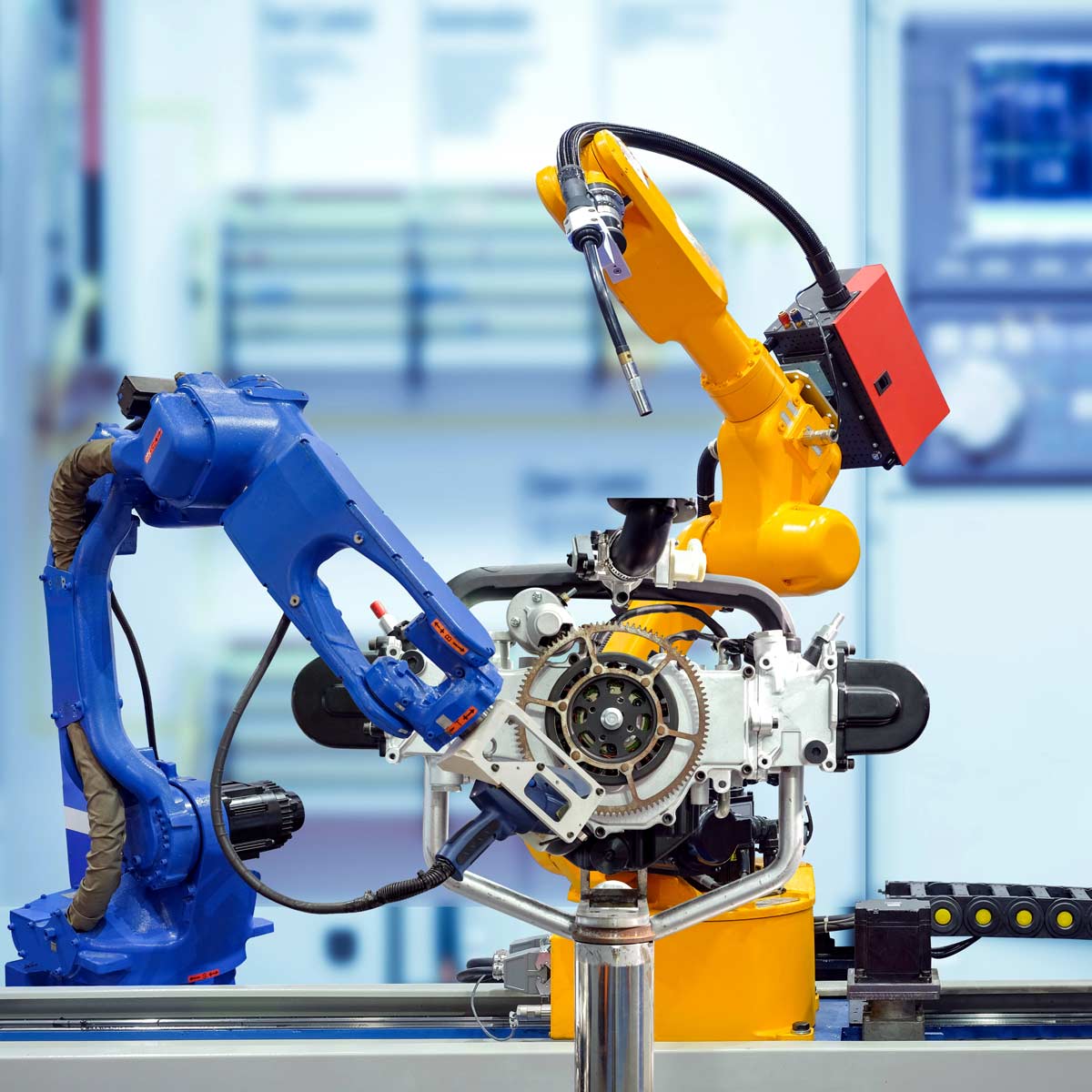

- Robotics and Automation: The use of robots and automated systems to perform manufacturing tasks with precision and efficiency.

- Internet of Things (IoT): Connecting machines, sensors, and devices across the factory floor to collect and analyse data, leading to improved decision-making and operational efficiency.

- Data Analytics and Artificial Intelligence (AI): Leveraging big data and AI to optimise production processes, predict maintenance needs, and enhance product quality.

- Supply Chain Integration: Using digital tools to streamline and coordinate the entire supply chain, from raw materials to finished products, ensuring better communication and responsiveness.

Digital manufacturing enables companies to improve productivity, reduce waste, shorten product development cycles, and create more customised products, thereby gaining a competitive edge in the market.

Using Technology to Improve Processes and Productivity

Our expert Digital Manufacturing Consultants are equipped with the latest Industry 4.0 knowledge to support Manufacturers scope, source and implement digital technology to implement sustainable improvements in relation to automation.

All of our Digital Manufacturing Consultants have extensive, hands-on experience from the industry and are experts in the optimisation of technology improve manufacturing efficiency.

Digital Transformation

Digital transformation is no longer a choice, it’s a necessity. We guide businesses through the complexities of adopting digital technologies that enhance customer experiences, improve data utilisation, and foster innovation. From implementing cloud solutions and AI-driven analytics to optimising for mobile and web, our digital transformation strategies empower you to be more responsive and resilient in a fast-paced, technology-driven world.

Related Article:

Synergy of Lean Culture and Digital Transformation in Manufacturing